Chrome plating is a process of applying a thin layer of chromium onto a metal surface through electroplating. The shiny, mirror-like finish of chrome makes it a popular choice for decorative purposes on everything from automotive parts to bathroom fixtures. But chrome plating also serves important functional purposes like preventing corrosion, facilitating cleaning, and increasing surface hardness.

The diagram illustrates the key steps in sequence:

- The substrate enters the cleaning stage where it is cleaned and rinsed.

- Next, the substrate enters the activation stage where the surface is activated.

- The substrate then enters the chrome plating bath where the chrome layer is plated onto the surface.

- After plating, the chrome bath sends the substrate to the rinsing stage.

- In the rinsing stage, the substrate is rinsed and dried, completing the process.

The diagram visually represents the sequential process flow during chrome plating. The labeled process blocks connected by arrows indicate the order of the stages and movement of the substrate between them. This provides a clear overview of the chrome plating steps.

What is Chrome Plating?

Chrome plating refers to the process of electroplating a thin layer or coating of chromium onto a metal object or part. Chromium provides a bright, shiny, mirror-like finish when plated, which is why chrome plating is most commonly associated with decorative uses.

However, the chromium applied during chrome plating also provides a number of functional benefits:

- Corrosion resistance – The chromium metal surface is resistant to tarnish and corrosion, providing durable protection from rusting.

- Hardness – Chrome plating can significantly increase surface hardness, making it more resistant to scratching, peening, and wear.

- Friction reduction – A smooth chrome surface also reduces friction, which is advantageous for moving parts.

- Cleanability – Chrome offers a smooth finish that repels water and dirt, making parts easier to clean.

So while the luminous chrome aesthetics are visually appealing, chrome plating also has practical applications that improve longevity and performance.

Why Use Chrome Plating?

There are two primary categories of reasons for chrome plating:

Decorative Purposes

- Attractive “chrome” finish – The mirror-like shine is visually appealing and can enhance the look of objects.

- Highly reflective surface – Chrome reflects light and surroundings, creating an eye-catching effect.

- Enhanced aesthetic appeal – Chrome is used to improve the visual appeal of items.

- Status symbol – The shiny finish carries a prestige perception, used to display wealth or importance.

Functional Purposes

- Corrosion resistance – The chromium surface resists corrosion and rust, protecting the base metal.

- Wear resistance – Chrome is harder than stainless steel, providing scratch and peel resistance.

- Friction/drag reduction – The slippery surface lowers friction, ideal for moving parts.

- Chip and abrasion protection – Chrome adds a barrier against debris, grit, road/soil abrasion.

- Cleanability – Chrome repels water and dirt, making it easy to clean.

- Sterilizability – Chrome can be sterilized for use in medical and food service applications.

So whether you’re looking to add some decorative shine or utilize the functional benefits, chrome plating has a lot to offer. The reasons for chrome plating vary widely depending on the application and intended use.

Types of Chrome Plating

There are several types of chrome plating that provide different aesthetic styles and functional qualities:

Bright/Show Chrome

- Highly polished, smooth mirror finish with no visible texture

- Reflects images clearly like a mirror

- Also called “Smooth Chrome”

- Purely decorative purpose, offers no functional benefit

Satin Chrome

- Has a non-reflective matte or brushed finish

- Lower luster than bright chrome but more luster than brushed chrome

- Decorative purpose, some added corrosion resistance

Brushed Chrome

- Flat, non-reflective brushed metal texture

- More corrosion resistant than bright chrome

- Decorative purpose, some functional benefits

Hard Chrome

- Thicker plating layer up to 0.25 mm for increased wear resistance

- Used for industrial applications like hydraulic cylinders, rollers, piston rings

- Functional purpose, improves hardness and wear/abrasion resistance

Thin Dense Chrome

- Moderate 0.05-0.4 mm plating for a balance of decoration and function

- Resistant to wear and corrosion

- Used for automotive trim, bathroom fixtures, and more

Micro-Cracked Chrome

- Network of microcracks in the chrome surface

- Allows base metal to release trapped hydrogen, preventing blistering

- Used for aerospace and military applications

Trivalent Chrome

- Uses trivalent Cr ions instead of hexavalent Cr ions found in other chrome plating types

- More environmentally friendly process

- Meets regulations banning hexavalent chromium

This overview shows how chrome plating can be tailored in thickness, finish, and other qualities to suit the specific application and needs, whether decorative or functional.

The Chrome Plating Process Step-by-Step

Chrome plating involves multiple steps to prepare, plate, and finish the part surface. Here is an overview of the complete electroplating process from start to finish:

1. Surface Preparation

- The surface must be thoroughly cleaned to remove dirt, oils, rust, old coatings and any other contaminants that may interfere with plating adhesion.

- Cleaning methods include solvent cleaning, hot soak cleaning, and abrasive blasting.

- A chemical pre-dip etch may be used to clean the surface and improve adhesion.

2. Surface Activation

- The part surface is activated to facilitate plating.

- Activation is done by immersing the part in an activation bath chemistry containing an acid etchant.

- This etches the surface to remove oxides and improve surface porosity.

3. Electrocleaning

- The part is electrocleaned by making it the cathode while immersed in an alkaline or acid electrolyte bath.

- This electrolytically removes remaining surface contamination for enhanced adhesion.

4. Rinsing

- The part must be thoroughly rinsed after each stage to prevent solution carryover.

- Rinsing is done by spraying or immersing the part in a tank of clean water.

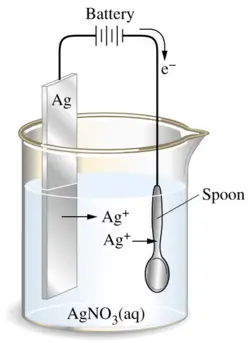

5. Plating

- The part becomes the cathode while immersed in a temperature-controlled chromic acid plating bath containing chromic, sulfuric and hydrochloric acids.

- The chrome anode dissolves, releasing Cr ions that deposit onto part surface.

- Plating time and current determines chrome layer thickness.

6. Post-Treatment

- Post-treatment enhances corrosion protection and aesthetics.

- Common post-treatments include hot water rinsing, chromating, and sealing.

This overview shows the key steps involved in chrome plating. Variations in process details, equipment, and parameters exist depending on the plating shop and specific application needs.

Chrome Plating Process Chemistry

The chemistry behind the chrome plating process involves chromic acid and other bath additives to deposit and treat the chrome coating:

Chromic Acid

- Provides Cr ions for chrome deposition onto the cathode.

- Hexavalent Cr or trivalent Cr compounds used to make the chromic acid plating solution.

Sulfuric Acid

- Improves conductivity of the plating bath.

- Increases plating speed and efficiency.

Hydrochloric Acid

- Helps keep plating bath free of metallic contaminants.

- Adjusted to achieve optimum plating brightness.

Catalysts

- Catalysts like chloride ions enhance the kinetics of Cr ion reduction and deposition.

- Improves plating uniformity.

Additives

- Organic additives like wetting agents improve solution penetration into recesses for better coverage.

- Brighteners refine grain structure for smoother, brighter finishes.

Anodic Treatments

- Sulfuric acid anodizing improves corrosion resistance.

- Chromic acid anodizing thickens and hardens chrome coating.

This overview demonstrates how various process chemistry components work together to facilitate high quality chrome plating and post-treatment.

Chrome Plating Equipment

Chrome plating requires specialized plating equipment to handle the process chemistry, electrical requirements, and workpiece parameters involved:

- Rectifiers – Provide DC power for the electroplating circuit. Control amperage required for chrome plating.

- Plating Tanks – Corrosion-resistant non-conductive tanks made of materials like plastic or polypropylene. Hold plating and treatment solutions. May be heated.

- Anodes – Insoluble lead or antimony-lead allow anodes dissolve to release Cr ions for plating.

- Racks and Fixtures – Hold parts in place and allow electrical contact during plating. Often made of titanium.

- Solution Agitation – Pump and filtration systems agitate solutions and prevent buildup of plating impurities.

- Process Hoists – Move parts from tank to tank in an automated sequence using hoists or cranes.

- Air Knives – Remove excess solution clinging to parts between process stages.

- Fume Scrubbers – Extract, filter and clean exhaust air to remove acid fumes.

Proper chrome plating equipment allows process parameters like solution temperature, dwell times, amperage, filtration rate, and part motion to be precisely controlled for high quality, consistent results.

Chrome Plating Design Considerations

Certain part design factors should be considered to ensure satisfactory chrome plating results:

- Material – Part must be electrically conductive for plating. Steel is commonly plated. Cannot plate aluminum or non-metals.

- Geometry – Complex shapes with recesses may have poor solution penetration. Deep holes will be unplated on inner surfaces.

- Masking – Areas that shouldn’t be plated must be masked with plater’s tape, lacquer, or wax.

- Surface Finish – Smoother pre-plate finish allows for higher quality chrome plating. Avoid rough surfaces.

- Stresses – Internal stresses in part can cause plating cracks or blisters. Stress relieving pre-treatments may be required.

- Contamination – Grease, paint or other contaminants will result in plating defects if not thoroughly cleaned.

- Corrosion – Severe rust or old coatings must be removed for quality plating.

Considering these factors in early design stages helps avoid issues during the plating process and achieve maximum chrome quality. Consulting with plating experts is recommended.

The Pros and Cons of Chrome Plating

Here is an overview of the key advantages and limitations of chrome plating:

Pros:

- Highly attractive decorative appearance

- Excellent corrosion resistance

- Improved wear and abrasion resistance

- Good lubricity and friction reduction

- Added surface hardness and durability

- Easy to clean and sterilize

Cons:

- Expensive process requiring specialized equipment

- Environmentally damaging hexavalent chromium may be used

- Limited corrosion protection for base metal at edges and holes

- Requires part to be electrically conductive

- Internal stresses can cause cracking or plating blisters

- Difficult to plate very rough, pitted surfaces

The benefits of an attractive finish and improved functional properties make chrome plating ideal for many applications. But the cost and potential environmental impacts are downsides to consider.

Chrome Plating Applications

Chrome plating is used across a diverse range of applications, both for decorative and functional purposes:

Automotive – Bumpers, trim, wheels, engine parts

Motorcycle – Frames, handlebars, parts

Marine – Boat propellers, fittings, railings

Bathroom – Faucets, showerheads, towel racks

Furniture – Table legs, chairs, cabinets, lighting

Hardware – Doorknobs, fasteners, tools

Military – Gun barrels, missile casings, vehicle and aircraft parts

Aerospace – Landing gear, engine parts, satellites

Industrial – Rollers, molds, process equipment

Medical – Surgical tools, implants, healthcare equipment

This wide range of applications demonstrates the versatility of chrome plating for enhancing aesthetics and performance across many industries.

Other Common Plating Processes

While chrome plating is a popular finishing process, there are alternatives that offer different benefits:

- Nickel – Provides corrosion protection at low cost but with less luster than chrome. Often used as undercoating before chrome plating.

- Cadmium – Corrosion resistant like chrome but restricted due to toxicity. Being phased out and replaced.

- Zinc – Most widely used anti-corrosion coating. Applied by hot-dip galvanizing, electroplating, and other methods.

- Tin – Primarily decorative but also electrically conductive and corrosion resistant.

- Gold – Extremely corrosion resistant and conductive. Very expensive but valued for prestige.

- Silver – Tarnishes easily but is attractive, conductive, and antimicrobial when plated thickly.

- Copper – Mainly decorative finish but also conductive and antimicrobial. Prone to corrosion.

The specific needs of an application ultimately determine the ideal type of plating process to use. Chrome plating offers an unparalleled combination of aesthetics, protection, and functionality.

Conclusion

Chrome plating is a versatile metal finishing process that provides beautiful mirror-like aesthetics and important functional benefits like enhanced hardness, wear resistance, cleanability, and corrosion protection.

While frequently associated with decorative uses like automotive trim and bathroom fixtures, it also serves critical roles in demanding industrial, aerospace, and military applications.

Electroplating a thin layer of chromium onto parts involves extensive preparation work, carefully controlled process chemistry and parameters, specialized equipment, and post-treatment steps.

When properly designed for and executed, chrome plating provides unbeatable performance and eye-catching appeal, making it a go-to finishing technique for all types of metal components and products.